TECHNOLOGY

Why we made up our mind to develop the Routerbee

The Kyoto Protocol was adopted in 1997.

Legal revision of deregulation of power industry was performed in 2000. These

facts caused us to feel the prospect of energy problems. And also, we

considered that all facilities consumed enormous quantity of electric power

would have to be supervised and controlled by effective ways for conservation

of energy, might be needed to solve these problems. A lot of stand-alone

industrial computers ware already under operation for supervisory and

controlling for these facilities in the world. Communication network was also

available here. One of the most effective ways to solve problems was expected

that all stand-alone computers under operation would communicate each other in

order to control these facilities together via communication network. Here, it

was needed to provide additional new function for each current computer, in

order to operate facility by an effective method. Unfortunately, software of these

computers ware usually designed based on stand-alone environment and installed

by deregulated ways, caused to serious problems to provide the additional

functions for each computer, which is under operation.

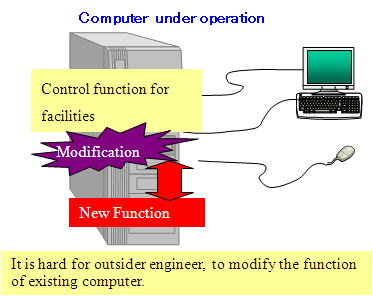

Only the engineer who had designed just

these computers, are able to do these works of improvement of function, or to

provide new function for current computer. That is, it was very difficult for

the 3rd person to do this work for computer, which once began to operate.

We made up our mind to solve these

problems, and lunched out into development in 2003.Fundamental design of

application software of current computer under operation had no open

environment, caused to prevent the 3rd person form improvement of function, or

to provide new function.

O Automatic operation for energy

conservation

For example, the function for excellent energy conservation, which those who manufacture a function developed can be used by computer under operation, independent of maker and form.It is called so to speak multi vendor.

O

Remote supervisory control and data acquisition

The excellent supervisory control and

data acquisition function which those who manufacture a function developed can

also be treated similarly.

We will do effort for research and development in order to provide more

advanced functions in which such an effect is expected.

Core Technology

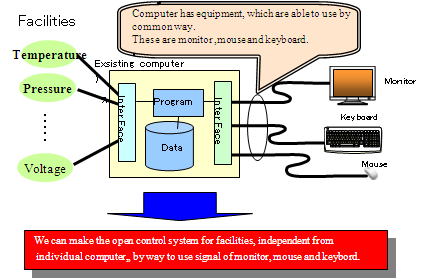

Industrial computer usually is provided

the fundamental function to show the states of facilities, as well as the

function to control facility to change state, as operator aimed. Here, he can

know the current state of facilities correctly by monitoring the screen of a

computer.

<

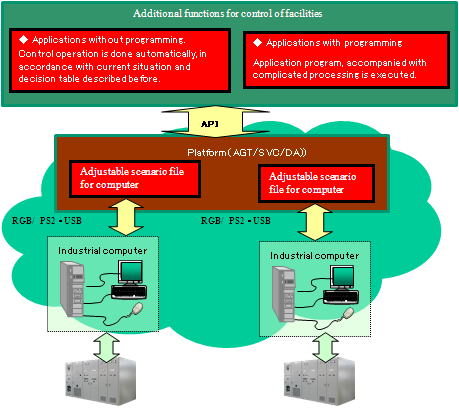

Multi-Vender Platform

Multi-vender environment for industrial

computer is available for system engineer of computer, to provide new functions

for automatic control of facilities. He is always free from restrictions causes

by computer maker or product specifications. He prepare macro commands

(scenario), in order to control facilities by way of graphic operation, which

consist of mouse and key board operations, such as start operation and change

status of air-conditioner etc., for individual computers.